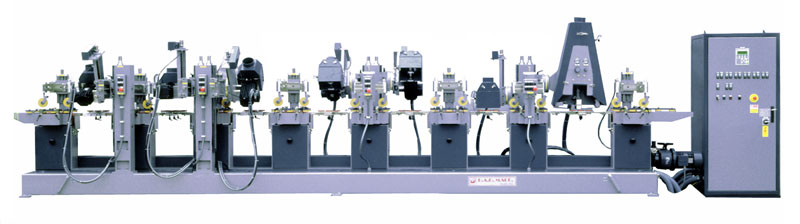

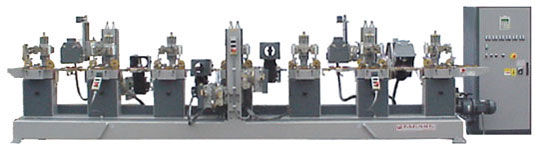

AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

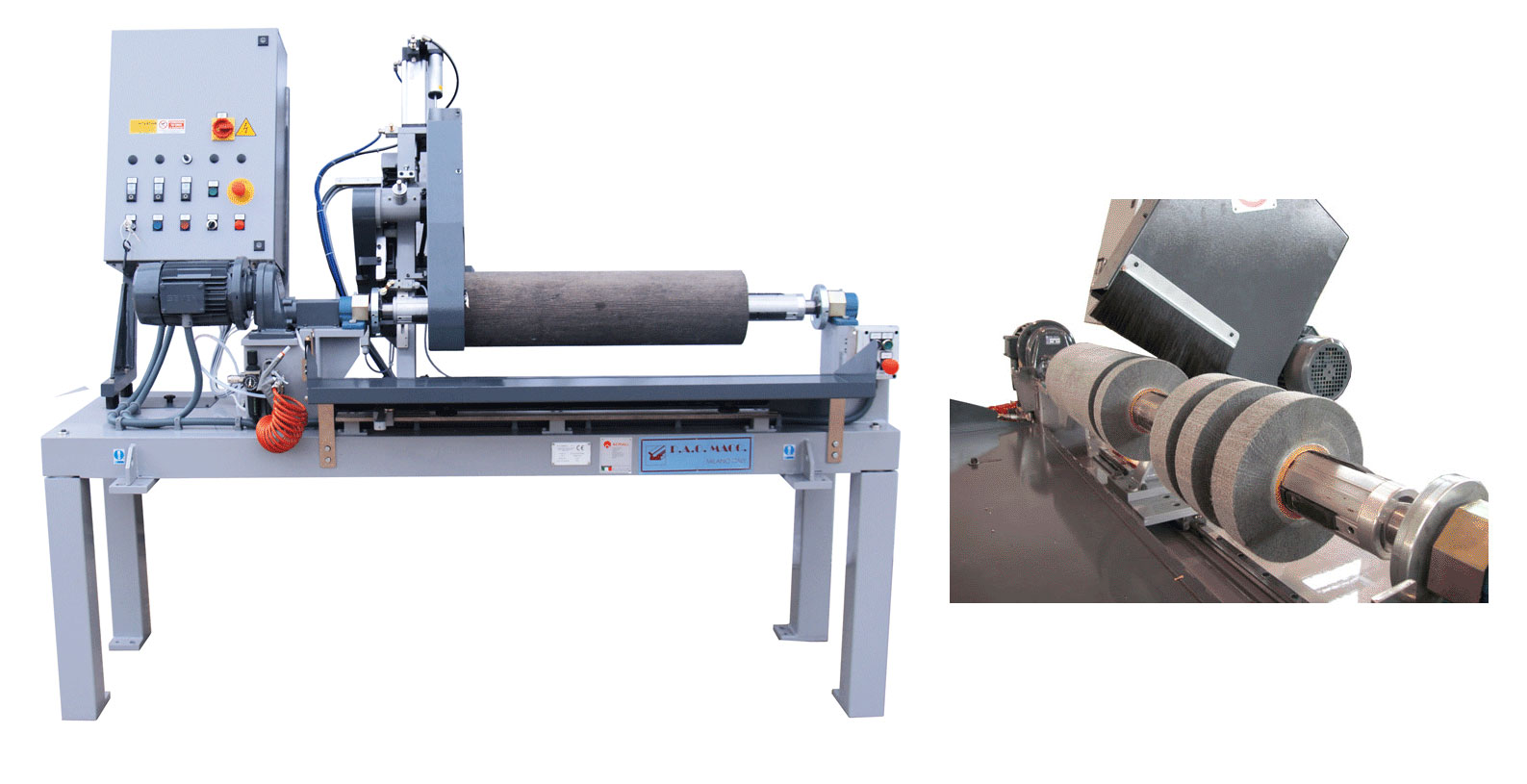

AUTOMATIC

SANDING MACHINE

AUTOMATIC

SANDING MACHINE

UNARGUABLY - STRONGEST - FLEXIBLE - RELIABLE

The machine is built with a solid structure of steel plate and tubular elements, electrically welded together to provide a high degree of solidity and stability. The machine has a conveyor system, with LINATEX belts . The conveyor is driven by a motor and gearbox, governed by Vector Inverter Siemens to provide different speeds suitable for any type of work. The sliding columns are positioned to the left / right side of the conveyor unit. The columns support the operating wheels, the vertical and horizontal slides as well as the inclined accurately with just one handle.

Standard Composition of the machine: ( Working Stations )

-Conveyor belts with side guides and upper guide pulleys.

-Sanding belts stations with Adjustable Speed Motors ( Brushless Servo Drives or Vector Inverter) from 280 to 2000 RPM.

Unit Details :

/Transport system

Linatex belts, 100 mm wide drive for initial thrust. Sprung upper guide pulleys with rubber wheels with bearing for the stability of the moulding. Guides with rubber wheels ( Dia. 70 x 15 mm. ) with dust-proof bearing. Vernier scale on the left side of the machine for perfect alignment of the guides.

The transport assemble is made with a Motor with Vector Inverter and with gear box, all connected with mechanical joints and shafts, directly on the driving pulleys. The transport don’t require any special maintenance

The conveyor speed can be regulated from 15 to 75 Mt./minute.( More ,Upon request ,for special application ).

Regulate the speed according to the required result of sanding : average speed for rough wood, high speed for varnish.

The side guides maintain the profile aligned ( by means of rods marked off in millimeters ) with the conveyor .

The upper guide pulleys are made with rubber rollers with spring ; they assure a perfect power and stability to the profiles. All Upper Pulleys are independently and can be positioning in different position.

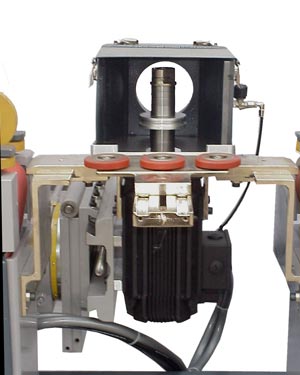

Coulisse, Uprights double/single slides complete with all slides ( Vertical - Horizontal- Inclination – 4 Axis for all cross motions) are positioning, on the left and on the right side hand, direct on the machine base. This system is a stability warranty with out any vibration. The unit is placed on the machine offset from one and another so that any unit has its conveyor belt before and after. Opposite motors are available only upon request.

/Sanding Stations.

Motor Sanding Wheels:

All Sanding Wheels Motor has 4 Hp . The machine can be configured with:

- Brushless Servo Drives

- Motor Governed By Vector Inverter

-

Single Speed Motor. ( 1400 ,at

50 cycles ,- 1690 ,at 60 cycles ,RPM ).

The power of all these motors is

constant for all rpm range. At ‘0’ RPM

the shaft is completely block. -(Usefully for very

delicate patina removal)-.

Any Kind of wheel ( hair, cloth or abrasive types ) can be fitted on the shafts of the motors and each motor expects a Kit of flanges fit for any type of wheel which is used. All motors can be tilted up to 90° as to the working table and up to 15° Transversally ( OPT ). All the wheels are sheltered in special casings embodying the coupling ( Dia. 120 mm. ) for connection to the suction system - excluded

Each wheels are provided with electron controlled down travel of the wheel. This is useful to program the automatic progress according to the abrasive wheel wearing. During the work, subject to programming from the PLC Siemens positioned on the control board panel. The wheel feed towards the profile of a tenth of millimeter while keeping the sanding degree constant for the whole life of the abrasive wheel.

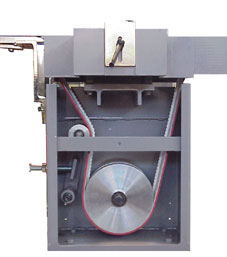

/Sanding Belt

All Sanding Belt Motor has 4 Hp. Each belts station can use sanding belt up to 2310 x 140 mm. 2310 are a fixed and standard size. All belts are sheltered in special casings embodying the coupling ( Dia. 120 mm. ) for connection to the suction system ( excluded ). Each sanding pad are provided with electron controlled down travel movement, ( for the profile’s beginning/end ) in according with the working speed ; this function are controlled automatically trough the PLC . All units are tilt able from 0° to 90° and provided with two kind of oscillation:

- The first one is hydraulic and move back and for the complete unit for flat surface.( Standard )

- The second is the possibility to move up and down only the sanding belt for small shaping profiles.( OPT )

SEE ALSO

> SANDING MACHINE ACCESSORIES

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2004 - paomacc -

info@paomacc.net