AUTOMATIC MACHINES AND WORKING FINISHING LINES FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

|

|

|

|

|

|

Home>OUR MACHINES>HOT STAMPING

|

|

|

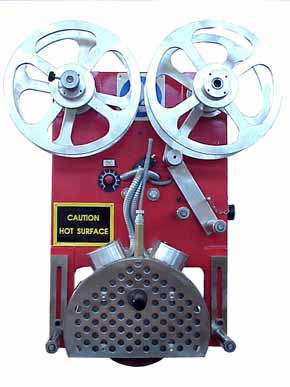

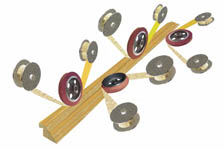

AUTOMATIC HOT STAMPING FOIL MACHINES The PAO MACC group Multi-Head Foiling Machine for lineal moulding originated in 1974. PAO MACC has produced more hot stamp foilers than any other manufactures in the world. Our experience and knowledge has assisted in the development of the most efficient and most cost effective hot stamp foil machine in the world. We addressed the need and high demand and superior quality for picture frame manufacturers around the world. This machine applies foils transfer decorative on mouldings/profiles manufactured on Wood, PVC, Polystyrene, Aluminium , etc.. Intricate profiles , flat and/or shaping or compo surface. can be effectively foiled with the use of this machines.

Each standard** foil head has two 1000 watt special heaters that heat the silicone foiling wheels. The temperature of the wheels is monitored by a special probe , with out any thermo-regulator : the thermo-regulation is electronically made by the PLC: the result of this control is perfect . The surface head is adjustable and controlled by the operator at the machine control panel. These heaters are Exceptionally efficient. As the foil is transferred, a take-up spool is electronically controlled through a variable speed motor, which collects the transfer film support . This speed control is located in front of the fixture that supports the foil head, foil supply spool and take-up spool. Molding transfer system consisting of 4" rubber caterpillar type belts, or steel and/or rubber wheels with ball bearing side wheel guides, and spring loaded top ball bearing wheel guides insure positive feed on the molding . The P.A.O. MACC. Multi-Head Foiling Machine will offer many years of accurate and superior quality, hot transfer foiling of any kind of profiles. ** Standard head : 80 mm. Wide - Special Heads can be supply up to 120 mm. wide. HOT STAMPING FOIL MACHINES SEE ALSO SPECIAL HOT STAMPING FOIL MACHINES FOR SPECIAL APPLICATION

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION Copyright(c) 2009 - paomacc - |

|

AUTOMATIC HOT STAMPING

FOIL MACHINES

AUTOMATIC HOT STAMPING

FOIL MACHINES