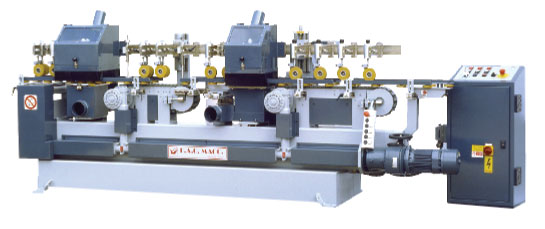

AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

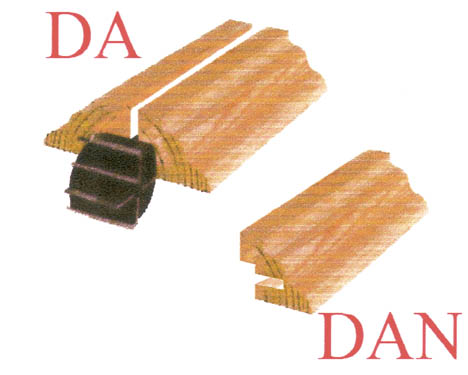

AUTOMATIC SPLITTER MACHINE DA MODEL AND

SPLITTER MACHINE WITH SIDES GROOVES STATION DAN MODEL

DA MODEL

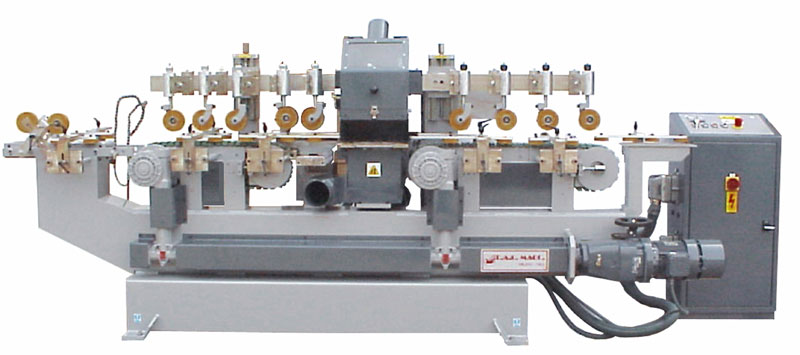

This machine is unarguably one of the strongest, most flexible, and most reliable available on the market.

The machine is built with a solid structure of steel plate and tubular elements, electrically welded together to provide a high degree of solidity and stability.

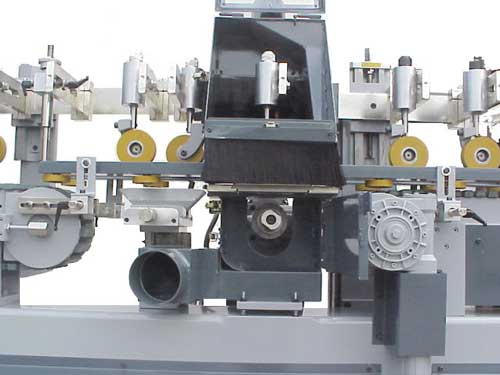

Composition of the machine:

1- In-feed Conveyor chain with side guides and sprung upper guide pulleys

2- Splitting Station with 10 Hp Motor

3- Adjustable moulding separating station

4- Out -feed Conveyor chain with side guides and sprung upper guide pulleys

DESCRIPTIONS OF THE OPERATING UNITS

1st.- and 4th. - Station

Double 5/8” neutral para rubber, 110 mm wide chain drive for initial / final thrust. The feed speed is adjustable through a 2 Hp speed variator ( The motor is With Mechanical Brake ) , from 9 to 45 Mt/minute

Sprung upper guide pulleys with rubber wheels with bearing for the stability of the moulding.

Guides with rubber wheels ( Dia. 70 x 15 mm. ) and bearing. Vernier scale on the left side of the machine for perfect alignment of the guides.

2nd. Station

Splitting station with 10 HP motor . The spindle and the tool are inside a safety casing ( with safety micro switch on the door ) according with the tool diameter (180 mm. ).The spindle is 40 mm. in diameter, and is pulley-belt driven. It runs at 7000 R.P.M. - Milling table is made of metal ( aluminium ) and is adjustable ( with slide) according to the tool size ( usually adjustable from 12 to 24 mm.).

Digital measuring devices make it possible to accurately adjust the machine each time.

3rd. Station

The moulding separation station consist in adjustable double guides (this movement is assures by a perfect coulisse ) ; and is able to assures perfect stability for the moulding as it split.

TECHNICAL FEATURES > DA MODEL

LENGTH :3.260 mm. WIDTH :1.200 mm. HEIGHT :1.300 mm. WEIGHT :1.170 KG. Installed power kW. 9 Conveyor motor power kW. 1,3 - HP 1,7 Splitter motor power kW. 7,5 - HP 10 Compressed air pressure 6 Bar (90 PSI) Air requirements Max. 800 nl/Min. SCFM -28 Working speed 9-45 Mt/min. Working Level 870 mm. Shaft diameter/revolution 40 mm. - 7.000 RPM Tool Diameter Required 200/220 mm.

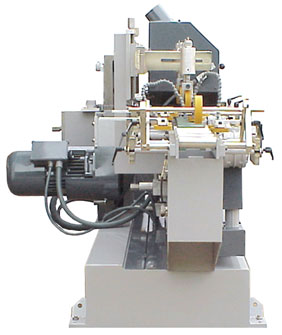

AUTOMATIC SPLITTER MACHINE WITH SIDES GROOVES STATION >DAN MODEL

The machine is built with a solid structure of steel plate and tubular elements, electrically welded together to provide a high degree of solidity and stability.

Composition of the machine:

1- In-feed Conveyor chain with side guides and sprung upper guide pulleys

2- Splitting Station with 10 Hp Motor

3- Adjustable moulding separating station

4- Out -feed Conveyor chain with side guides and sprung upper guide pulleys

5- Groove Station with 2 Hp Motor

6- Out-feed rollers

DESCRIPTIONS OF THE OPERATING UNITS

1st.- and 4th. - Station

Double 5/8” neutral para rubber, 110 mm wide chain drive for initial / final thrust.

The feed speed is adjustable through a 2 Hp speed variator, from 8 to 40 Mt/minute.

Sprung upper guide pulleys with rubber wheels with bearing for the stability of the moulding.

Guides with rubber wheels ( Dia. 70 x 15 mm. ) and bearing. Vernier scale on the left side of the machine for perfect alignment of the guides.

2nd. Station

Splitting station with 7,5 HP motor . The spindle and the tool are inside a safety casing ( with safety micro switch on the door ) according with the tool diameter (180 mm. ).The spindle is 40 mm. in diameter, and is pulley-belt driven. It runs at 7000 R.P.M. Milling table is made of metal (aluminium) and is adjustable (with slide) according to the tool size (usually adjustable from 12 to 24 mm.). Digital measuring devices make it possible to accurately adjust the machine each time.

3rd. Station

The moulding separation station consist in adjustable double guides (this movement is assures by a perfect coulisse ) ; and is able to assures perfect stability for the moulding as it split.

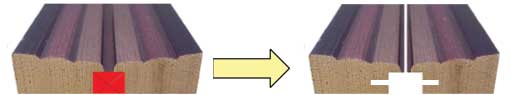

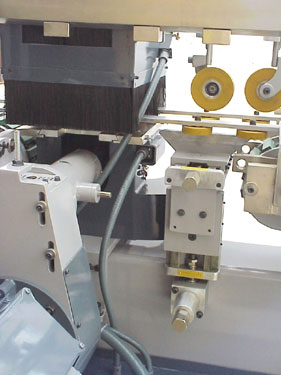

5th. Station

Groove Station with 2 Hp Motor.

With this unit as the moulding is split, it is separated by a shoe prior to a horizontal groove. Grooves will be cut both left and right moulding pieces.

6. Station

Out-feed rollers ; two motorized aluminium rollers , with upper pulleys , help the extraction of the separated mouldings.

TECHNICAL FEATURES > DAN MODEL

Installed power Kw. 11

conveyor motor power kW. 1.1

Splitter motor power kW. 7.5 - HP 10

Groove motor power KW.1,5

Compressed air pressure 6 Bar (90 PSI)

Air requirements Max. 800 nl/Min. SCFM 28

Working speed 8-40 Mt/min.

Working Level 870 mm.

Splitter :

Shaft diameter and revolution : 40 mm. / 7.000 R.P.M.

Maximum tool diameter : Dia. mm. 180

Groove:

Shaft diameter and revolution : 22 mm. / 6.000 R.P.M.

Maximum tool diameter : Dia. mm. 80/100

Complete SOUND-PROOF cabin for DA and DAN Models - with safety micro-switch on the doors - neon lights - all fitting element ready to connect to the main dust vacuum system.

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2004 - paomacc -

info@paomacc.net