AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

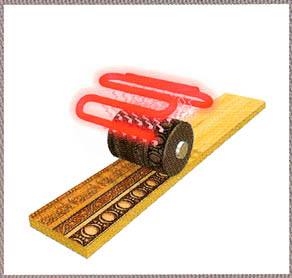

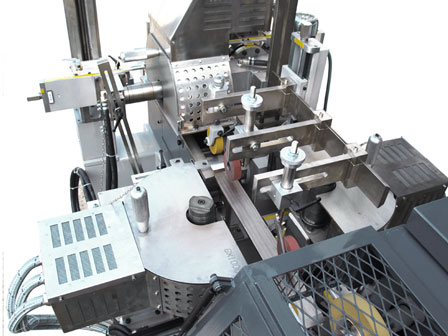

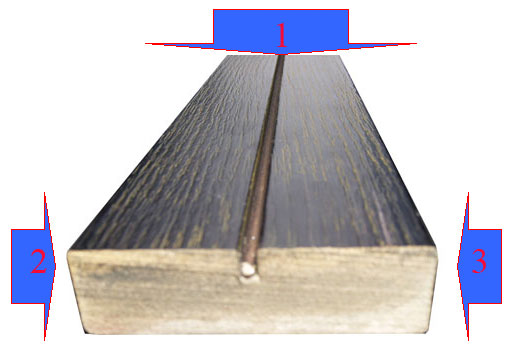

The conveyor is driven by a motor and gearbox with Vector Inverter to provide different speeds suitable for any type of work. The sliding column is positioned to the side of the conveyor unit. The column support the operating head, the vertical and horizontal slides as well as the inclined accurately with just one handle. The head is used for directly hot-engraving wood or plastic profiles. Engraving is performed by means of a pressing cylinder, heated electrically by means of resistors and brought to a maximum admissible temperature of 650°C ( the temperature depends on the type of wood/PVC and the degree of engraving, ).The engraving shaft is supported in booth side trough a vertical column and a special supports. The temperature is maintained constant by an electronic precision thermostat and a probe housed near the heating grille. The assembly can be tilted from 0° to ± 45°.

The shaft of the engraving roll is cooled constantly with water (emulsifiable with chemical oil) which is taken from the tank formed in the base of the machine and circulated by means of a pump. The engraver shaft, during machining, is rotated by the movement of the profile. In the absence of the moulding however the shaft rotates on its own, thanks to the aid of a pneumatic clutch controlled by a PLC Siemens. During the heating and cooling phase the engraving roll has to rotate to allow homogeneous heating and vice versa. (At least 15 minute).

The side guides maintain the profile aligned (by means of rods marked off in millimetres) with the rollers conveyor. In the beginning of the machine the side guides are made with rubber wheels, while in the end, near the engraving head are made with flat nickel plated steel pieces.

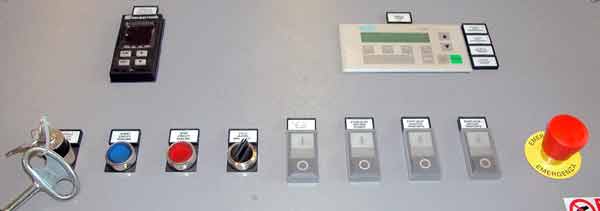

ELECTRICAL

HEAT EMBOSSING MACHINE

ELECTRICAL

HEAT EMBOSSING MACHINE

- PC/TR1D MODEL -

The machine is built with a very solid structure of steel plate and tubular elements, electrically welded together to provide a high degree of solidity and stability. The machine has a conveyor system, with steel driving wheels 100 mm wide in the bottom and three upper Rubber driving wheels controlled by pneumatically system ( no mechanical adjustment required ).

TECHNICAL FEATURES:

LENGTH 2.600 mm. ( + Electrical control table 950 mm. )

-3.600 mm. If the machine is with final rollers.( OPTional )

WIDTH 950 mm.

HEIGHT 1.600 mm.

WEIGHT 1.200 KG. ( WITH OUT COOLING WATER )+ Kg.150 ( Control table)

Total Installed power KW. 10

- Total Amperage 14 AMPERES

- Working speed 2-30 MT/min.

- Engraving shaft diameter D. 60 mm.

- Engraving roller diameter Min. D.220 mm.- 250 mm. Max.(250 >>RECOMMEND)

- Conveyor motor power Kw. 2.2

- Working Level 870 mm.

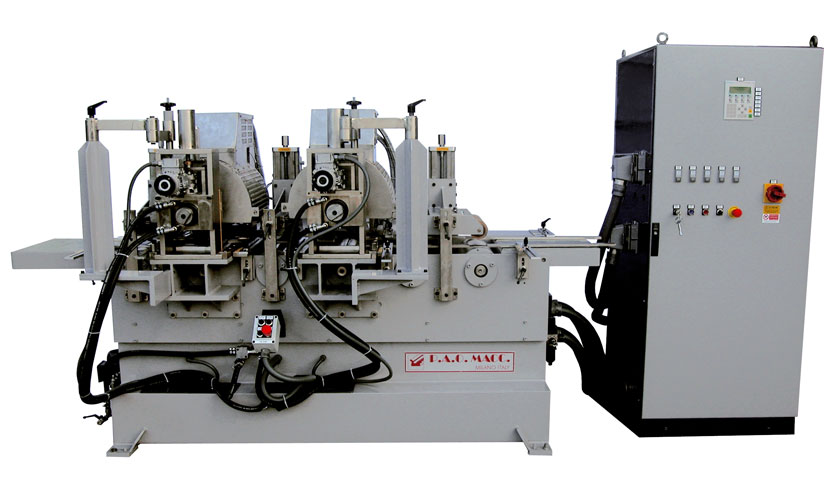

TWO HEADS ELECTRICAL HEAT EMBOSSING MACHINE

FOR PANELS, PARQUETS ETC.

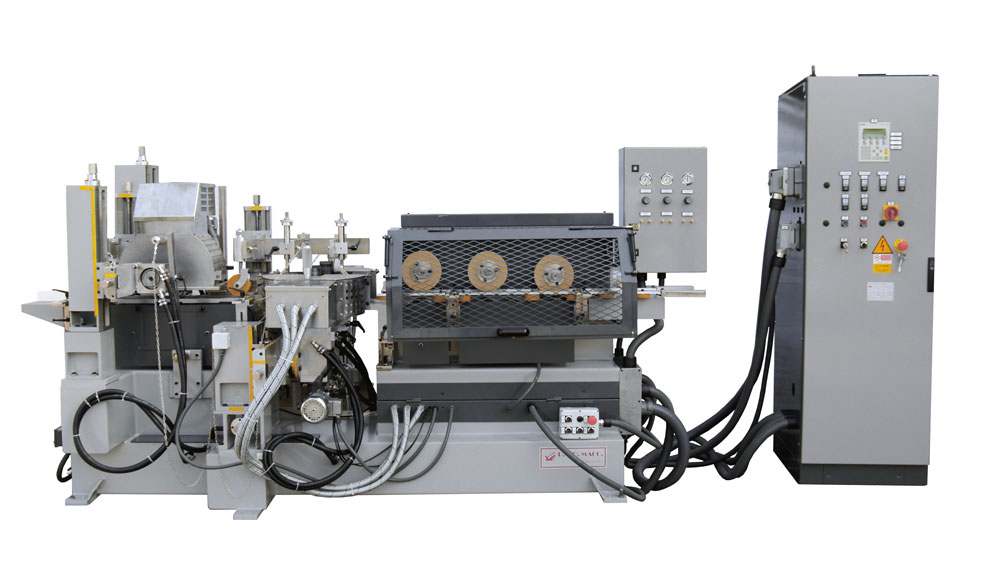

THREE

HEADS ELECTRICAL

HEAT EMBOSSING MACHINE -FOR PROFILES

THREE

HEADS ELECTRICAL

HEAT EMBOSSING MACHINE -FOR PROFILES

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2009 - paomacc -

info@paomacc.net