AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

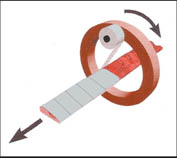

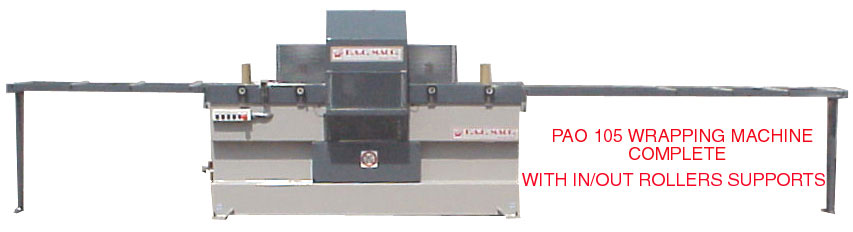

AUTOMATIC WRAPPING MACHINE > PAO 105 MODEL

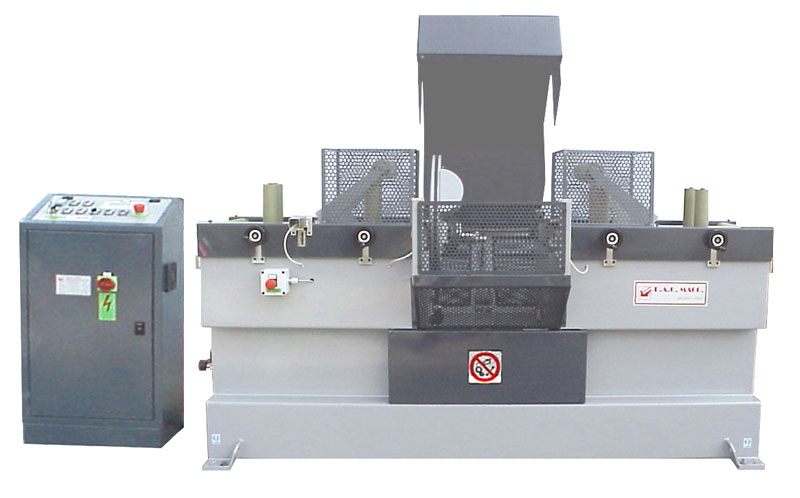

GENERAL DESCRIPTION OF THE MACHINE AND OF ITS INDIVIDUAL COMPONENT PARTS

The machine is built with a solid structure of large steel sheets, welded together electrically in order to provide stability and solidity.

The machine has a lower conveying system with rubber drive rollers. The upper pressure rollers in para are however idle and actuated automatically by self-adjusting pneumatic cylinders.

The machine has two different electronic programs which allow it to be used by two operators or only one. It also has variable speeds for both the conveying system and the speed of rotation of the paper-holder winder bearing.

1 Conveyor system

The machine has a conveyor system with driving rollers covered in rubber and connected to each other by a single 1/2" chain system. The whole assembly is moved by means of a speed variator which enables regulation from 4 to 20 mt/minute. All the chains are protected and placed inside protective casings screwed to the shell of the machine. Internally the chains are kept tight by means of rotating tightener.

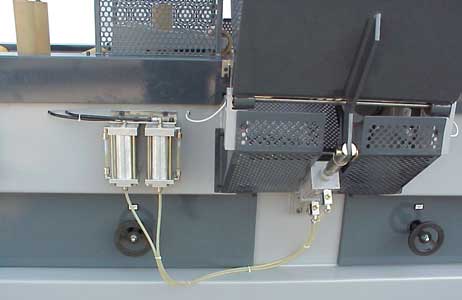

2 Upper presses

The machine has two upper automatic presses controlled by photoelectric cells and moved by pneumatic cylinders adjusted to low pressure (ensuring the necessary thrust pressure without any damage to the mouldings). Their normal working pressure (with independent regulation of the rest of the machine) is 1.5 - 3 bar max.

The first press comes into operation when the profile reaches the second photoelectric cell and when the third is reached the outlet press is actuated. Each press has speed regulation in both directions (up/down).

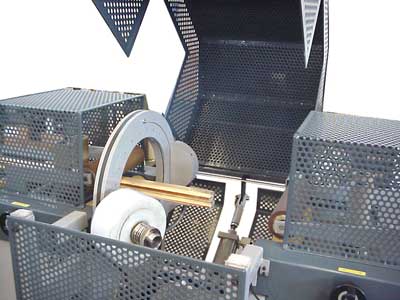

3 Winder bearing

The winder bearing is made totally in steel (internally hardened) with balls in DERLIN (a self-lubricating material).

The bearing is made to rotate by a belt with the aid of a speed variator which allows a range of regulation from 90 to 450 rpm. The motor used is self-braking which allows the unit to be blocked completely. The roll-holder head is installed on the shell and has been designed with a release system, which can be rapidly actuated to change the roll of paper.

Some technical features of the machine allow the use of micro-perforated PVC rolls or white paper, thanks to the friction assembly on the shell of the roll-holder head which can regulate the winding force.

4 Self-centring lateral rotating guides

Three units of these self-centring guides allow perfect automatic alignment of the profile (or of the bundle of profiles).

Regulation takes place by means of convenient hand-wheels positioned on the operator working side. The guides have no reference with Vernier scale in that they always ensure perfect alignment of the profiles in the centre of the winder bearing by means of threaded systems (right/left).

5 Roller assemblies (OPTIONAL)

The roller assemblies complete independent operation of the machine (a table can also be used), ensuring support for the profile before and after processing. This enables the operator (or operators) to fasten the top of the paper with sticky tape and to tear the paper between one profile and the next.

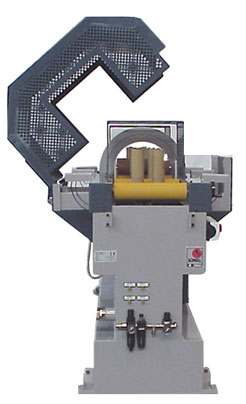

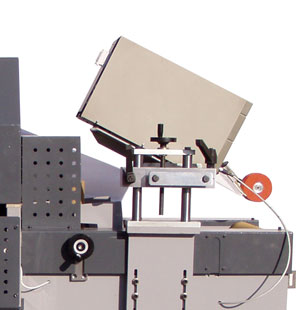

6 Bearing's Protection

The protection guard is controlled automatically during the automatic phase and is driven by a hydraulic cylinder. With the protection guard closed and the Safety micro-switch engaged, rotation of the bearing cannot be actuated.

The hydraulic cylinder is fed by two oil tanks which ensure regular motion without sharp accelerations which could jeopardize proper closure.

TECHNICAL DETAILS :

LENGTH : mm. 2.300 ( WITH IN-OUT ROLLERS MM. 8.000 )

WIDTH : mm 1.300

HEIGHT : mm. 1.850

Weight : KG. 1.100

Number of conveyor rollers : 6

Number of pneumatic upper guide pulley . 2

Compressed Air pressure 8 Bar (118 PSI)

Air requirements (Max.) 130 Lt/min - 4.60 SCFM

Installed Power Kw. 3

Working Speed 4-20 mt/minute

Working Level 870 mm.

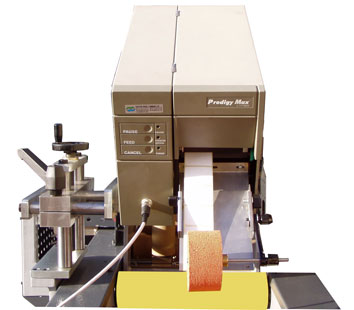

OPTIONAL >LABEL PRINTER APPLICATOR MACHINE

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2009 - paomacc group-

info@paomacc.net