AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

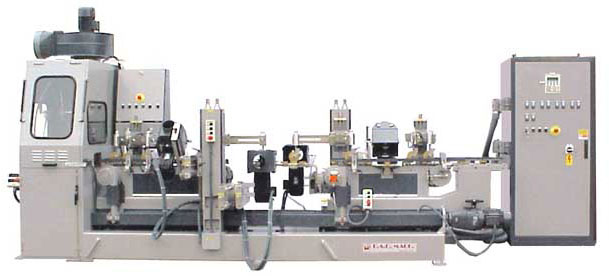

AUTOMATIC PATINA MACHINE - PA/ MODEL

GENERAL DESCRIPTIONS OF THE MACHINE

The machine is built with a solid structure of steel plate and tubular elements, electrically welded together to provide a high degree of solidity and stability. Specialized Machine designed for finishing of pictures frame moulding. Complex finishes can be achieved by several different operations working simultaneously or one at a time ( Working Stations ) . The most difficult profiles can be processed with this machine. Each machine is designed and built to meet the specific needs of each Customer. The machine combines several stations each of which can execute different operations. Aluminium arches with steel brushes to scratch foil or finish. Bank of variable speed motors - Brushless Servo Drives adjustable By PLC from `0'- to `2000' RPM , at constant power - for buffing or special effects , striping heads for paints stripes, spray booth for patina continuous or intermittent spray or distressing effect and wiping tunnel for antiquing effect. Moulding is transferred by a positive system of a caterpillar-type belt comprising 1/2” thick rubber, 7/8” wide 4,5” long links and top and bottom rollers to ensure consistent stability in material transfer.

DESCRIPTIONS OF THE OPERATING UNITS

-Transport Double 5/8” neutral para rubber, 110 mm wide chain drive for initial thrust. Sprung upper guide pulleys with rubber wheels with bearing for the stability of the moulding. Guides with rubber wheels ( Dia. 70 x 15 mm. ) and bearing. Vernier scale on the left side of the machine for perfect alignment of the guides.

-Scratching Station - 2-3- or 4 arches in aluminium (with 6-9 or 12 peeling heads). The heads are swinging in any direction and equipped with support for fitting of a steel brush which can vary in size. Each arch expects two blowers for the continuous cleaning of the brushes.

-Sanding - Buffing and Patina removal Motors -

Uprights slides-colons with Brushless Servo Drives Motors , 4 HP each, with electronic controlled variable speed from 0 to 2000 rpm. ( the motors power is constant for all rpm range ). The motors are assembled on horizontal and vertical slides for all cross motions. All motors ( on the right or and on the left ) can be tilted up to 90° as to the working table and up to 15° Transversally ( OPTIONAL ). Any Kind of wheel ( hair, cloth or abrasive type ) can be fitted on the shafts of the motors and each motor expects a Kit of flanges fit for any type of wheel which is used. All the wheels are sheltered in special casings embodying the coupling for connection to the suction system ( excluded ).

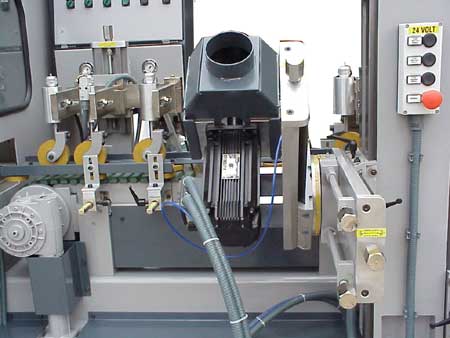

-Spraying Station

Complete Spraying booth equipped with 3 - 4 - 6 - 7 or more automatic spray guns . The spray guns are fed by a two - diaphragm pump for spraying of nitro - cellulose, synthetic or similar products. Atomisation control independent for each spray gun . The booth can be opened in one side and equipped with shock absorbers. Spray gun engagement is automatic and controlled by micro-switch; suction system with built-in cartridge filter ( 4 HP- 4000 mc/h. aspired engine ). Over the spaying booth are positioned one or more tanks for use one or more different paint colour in the same time. All the operating guns are controlled automatically by a PLC Siemens with double working program : continuously and/or intermittence

-Final Wiping Tunnel

Final section for varnish lay off ( wiping tunnel ). It consists of an horizontal support with side guides for the side wheels not to damage the previously accomplished process. The support is fit for assembling of a rubber sponge wrapping system on the profile ( or industrial cotton-waste ) and paint-brushes. This final section of 1,4 Mt. length enables one or two operators to carry out manual operations such as lay off of the varnish. This final wiping tunnel in same case ( upon request ) is possible to be positioned inside of the spray booth.

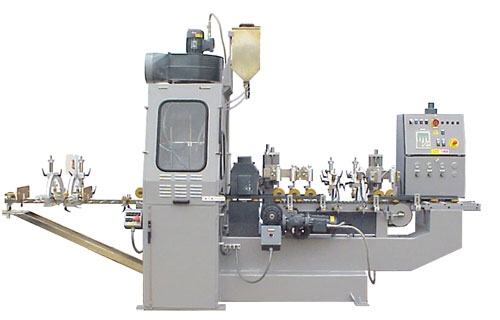

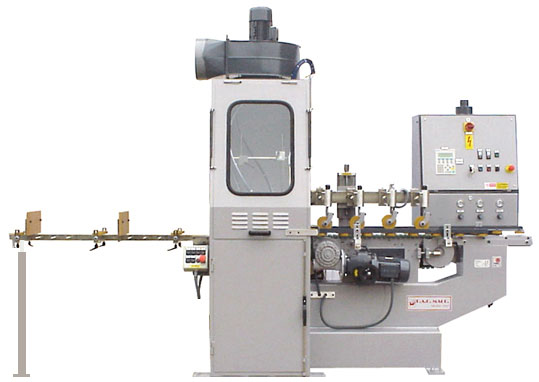

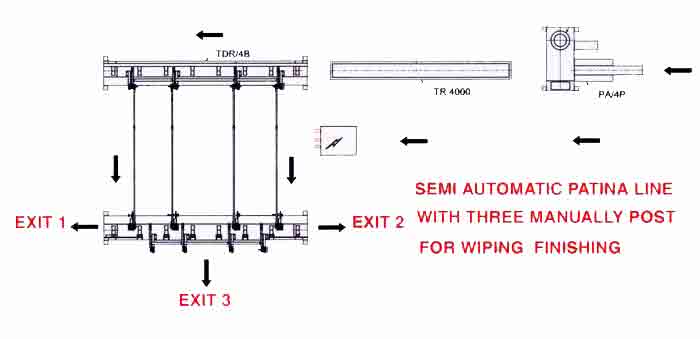

SEMI-AUTOMATIC PATINA WORKING LINE FOR SPECIAL APPLICATION

WITH THREE MANUALLY WIPING POST- ALL THE HANDLING OPERATIONS ARE AUTOMATICALLY AND CONTROLLED BY PLC SIEMENS

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2009 - paomacc group

-

info@paomacc.net