AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

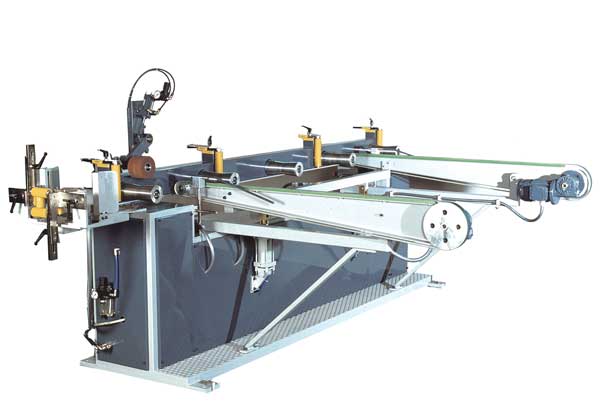

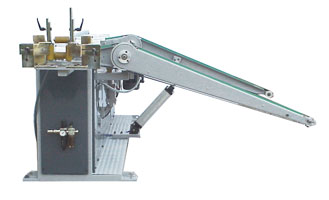

HORIZONTAL LOADER MACHINE - TTF/2 MODEL

GENERAL DESCRIPTIONS OF THE MACHINE

This loader is suitable for automatically loading any machines. The machine can load only twin or any stable profiles.

The speed the loader can attain depends substantially on the length of the sections.

It has been shown experimentally that with rods all 3 meters long the loader can attain a maximum speed of 50/60 meters/minute. In the case of rods having a different length it is not possible to know the speed since the duration of the loading cycle is independent of the length. The machine consists two conveyor belt arms, where the operator loads the rods by hand. The operator deposits the rods, that have different lengths, not necessarily parallel to one another but he should place them so that the initial tips form a line as close as possible to the point of exit (after the first arm's detection photocell).

The machine also has a roller unit driven by a speed variator where it is possible to select a speed at which the rods leave the machine. This should be reasonably higher than that of the next machine.

The thrust presser to assist the rod in entering the next machine is positioned on the roller unit. The thrust time is adjusted with the Siemens PLC display on the control panel.

At the outlet from the roller unit a barrier photocell prevents the operation of the arm conveyors until the rod has left its field of detection.

MECHANICAL FEATURES OF THE INDIVIDUAL PARTS

Roller assembly.

The roller assembly is integral with the base and consists of conical aluminum rollers connected via cogged belts which are driven by a speed variator and which can be adjusted to the speed required.

The belts are protected by casings integral with the base. The variator is housed under the base itself, enclosed by casings attached by screws, whereas the hand wheel, for greater convenience of speed regulation, has been installed externally.

Arms

The arms ( TWO ) are supported by hardened supports and the up/down movement are made by means two pneumatically cylinder. Each arm consists of one belts and are operated by a separate motor ( NR. 2 ).

TTF/2 - TECHNICAL FEATURES :

LENGTH : 3.100 mm.

WIDTH : 1.930 mm.

HEIGHT : 1.300 mm.

WEIGHT : 500 KG.

Total Installed power : kW. 1,2

Number of the Arms : 2

Compressed air pressure : 6 Bar - 90 PSI

Air requirements : 130 nl/min SCFM 3.53

Working speed : Rollers 40-140 Mt/minute

Horizontal translation (arms belt): 9 Mt/min.

Length of the mouldings : Min. 1800 mm. - Max. 3.500 mm.

>For Different Length Upon Request<

Rollers Conveyor motor power : HP 1

ARMS belts motor : kW. 0.5 X 2

Working Level : 870 mm.

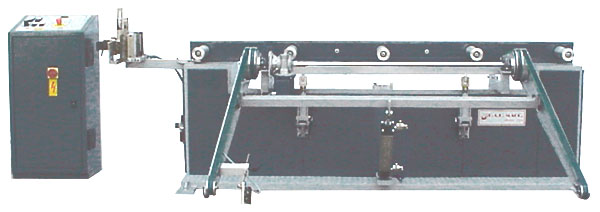

HORIZONTAL UN-LOADER MACHINE - TTF2/S

MODEL

GENERAL DESCRIPTIONS OF THE MACHINE

This unloader is suitable for automatically discharge any machines. The machine can unloading only twin or stable rods.

The speed the unloader can attain depends substantially on the length of the sections. It has been shown experimentally that with rods all 3 meters long the unloader can obtain a maximum speed of 50/60 meters/minute. In the case of rods having a different length it is not possible to know the speed since the duration of the unloading cycle is independent of the length. The machine consists in one exit rollers with two small belts arms . The rollers load the profiles and the small arms remove its and load others two long belts arms. The operation is completely automatic and in the rollers entrance a barrier photoelectric cell detective the profiles . The rods on the long belts arms are moving step by step and/or continuously , ( adjustable trough Siemens PLC ) to the end of these belts and than are deposit into a normal container. The long belts arm are start in the lower position and go up step by step, by a photocell, in according with the mouldings quantity into the container.

TTF2/S - TECHNICAL FEATURES :

LENGTH : 3.200 mm.

WIDTH : 2.250 mm.

HEIGHT : 1.300 mm.

WEIGHT : 500 KG.

Total Installed power : kW. 1,1

Number of the Arms : 2

Compressed air pressure : 6 Bar - 90 PSI

Air requirements : 130 nl/min SCFM 3.53

Working speed : Rollers 40-140 Mt/minute

: Horizontal translation (arms belt): 9 Mt/min.

Length of the mouldings : Min. 1800 mm. - Max. 3.500 mm.

For Different Length Upon Request

Rollers Conveyor motor power : HP 1

ARMS belts motor : kW. 0.5 X 2

Working Level : 870 mm.

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2004 - paomacc -

info@paomacc.net