AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

AUTOMATIC VERTICAL STACKER AND UN-STACKER MACHINES

RELIABILITY - SPEEDY - STRONGLY - EASY

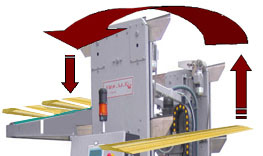

The vertical STACKER mod. SC2-SC3-SC4 was designed to handle and stack automatically linear strips, mouldings for picture frames etc. on shelved trolleys. The difference between one model and another consists merely in the number of the arms. The machine is suitable for handling double mouldings or in any case those which are reasonably stable. The machine takes the strips from other machines or from working lines and automatically, through cyclical phases, deposits them on the shelves of trolleys without any manual intervention from operators.

The strips are also deposited at a distance from each other so that, throughout the transfer cycle, they do not come into contact with each other or with any mechanical part of the machine. The machine is therefore particularly suitable for handling strips coming from spraying and plastering lines, where material which has not yet dried and hence is difficult to manipulate has to be handled. The machine has a set of rollers, where the mouldings coming from these lines are automatically conveyed and taken by suitable scoops which, via a vertical movement, constantly clear the rollers. The scoops are driven by chains and accompany the strips towards an upper horizontal conveyor belt. Here they are aligned and at the same time picked up by the scoops and translated to the other side of the machine. The operations are simultaneous and cyclical in that the mechanical configuration of the scoops is exploited, without the strips being unbalanced in any way. Further on in the cyclical phase, the strips are first of all straightened by means of a belt in constant motion and deposited on belt arms step by step. The step represents the distance between one strip and the other, and can be regulated electronically. With the arms filled the machine deposits all the strips present on the first shelf of the trolley and automatically moves to find a subsequent shelf.

A first sound signal warns the operator that the trolley is about to be filled while a second sound and luminous signal automatically blocks the machine and line. The operator then replaces the trolley with another empty one and the machine is ready for another cycle. All automatic operation are governed by a Siemens PLC.

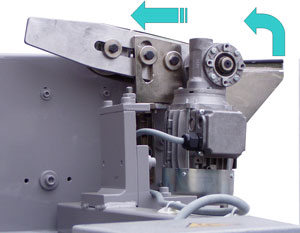

Exlusive P.A.O. MACC. patented upper blades horizontal translation. This system, without, any profiles rotation is synonemouus of a great stability and reliability. In addition to the traslation the device automatically align one more time all the profiles.

AUTOMATIC UN-STACKER, FEEDER, MACHINES

The vertical loader Model SC has been designed for the unloading of carriages and the automatic transfer of mouldings profiles for picture frames. The machine is fit to transfer intricate profiles and to ensure their stability.

The loader picks up the profile from the shelves of previously loaded carriages and without the intervention of the operator it can feed a machine or a processing line in cyclical stages. The machine has two/three or four arms, equipped with belts, which remove the profiles from the carriage and transfer them onto blades that in their turn free the belts through vertical translation. The blades are operated by chains and convey the profiles towards an upper horizontal traveling belt.

The profiles are here positioned and lined up then conveyed again to the blades and transferred to the other side of the machine.

These operations happen simultaneously and in a cyclical way since the mechanical configuration of the blades exploited and stability of the profiles is unsure. The profiles are then laid down on a roller conveyor to feed a machine or a processing line.

An audio-visible signal warms the operator that the carriage is empty and the machine stops automatically.

The operator sees to position a new carriage to unload and the machine is ready to start a new processing cycle.

All automatic operation are governed by a Siemens PLC.

GENERAL FEATURES FOR BOOTH MACHINES

LENGTH : 2.870 mm.

WIDTH (WITH TROLLEY) : 2.250 mm.

WIDTH (WITH-OUT TROLLEY) : 2.150 mm.

HEIGHT : 2.400 mm.

WEIGHT : 1.300 KG.

Total Installed power : Kw. 3.5-4,6 HP

Number of Arms : 2

Working speed : Rollers 15-75 Mt/minute

: Vertical translation (blades) : 11/55 cycles/minute

: Vertical descend (arms) : 10” for complete travel

: Horizontal translation (arms belt): 9 Mt/min.

Length of the mouldings : Min. 1.650-Max.3.500 mm.

Rollers Conveyor motor power : Kw. 0.75- Inverter -electronic brake

Blades motor : Kw 1.1 with electronic brake

ARMS motor (up/down travel ) : kW. 0.75 - Inverter -electronic brake

Upper translation motors (No.2) : Kw. 0.09

Lower translation motor(small belts) : Kw. 0.09

Arms translation belts motor : Kw. 0.25

Working Level : 870 mm.

All variable working speeds are without any mechanical speed variator, but

adjustable by means Siemens Inverters through the PLC display.

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2009 - paomacc group-

info@paomacc.net