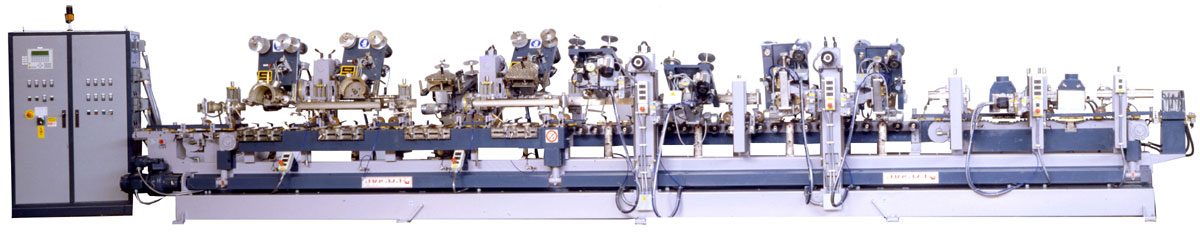

AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

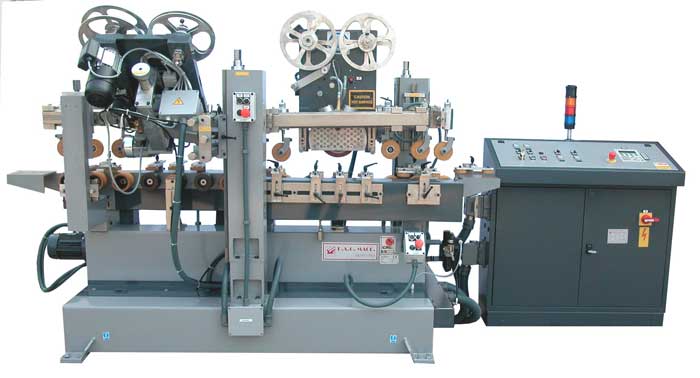

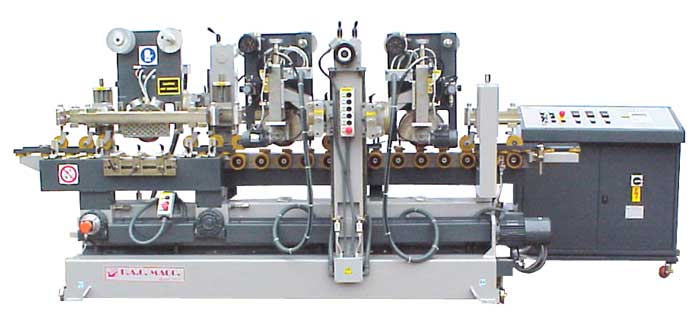

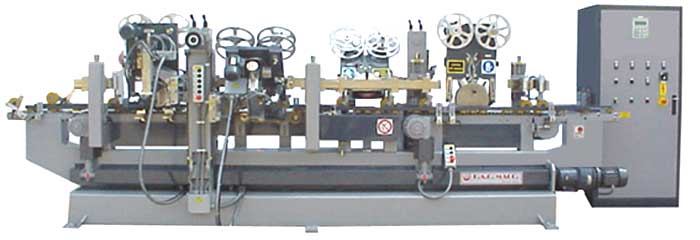

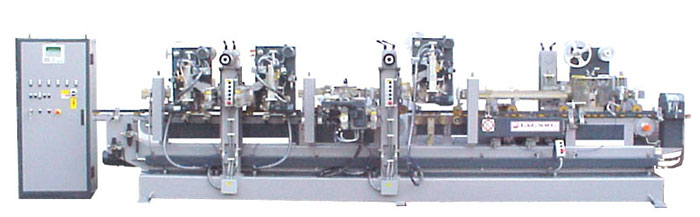

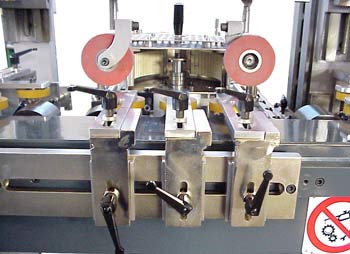

AUTOMATIC HOT STAMPING FOIL MACHINES FOR WOOD WITH GESSO PLASTER AND MDF PROFILES

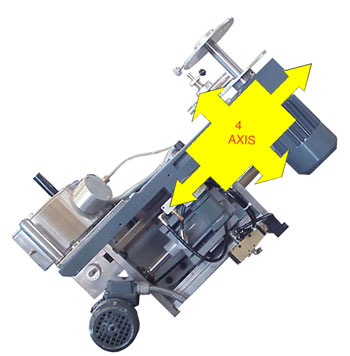

Intricate profiles , flat and/or shaping or compo surface, can be effectively foiled with the use of this machine. The DC Models are available with any number of heads, up to twelve (12), which are alternately placed on the machine. Each head is adjustable from 0° to 90°, by means of a veneer scale. An PLC SIEMENS controls the time foil head contact with the molding, keeping track of the lineal footage processed, feed speed of molding and many other important functions.

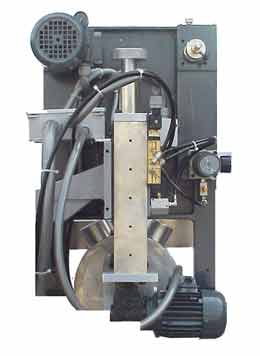

Each standard foil head has two 1000 watt special heaters that heat the silicone foiling wheels. The temperature of the wheels is monitored by a special probe , with out any thermo-regulator : the thermo-regulation is electronically made by the PLC: the result of this control is perfect . The surface head is adjustable and controlled by the operator at the machine control panel. These heaters are Exceptionally efficient. As the foil is transferred, a take-up spool is electronically controlled through a variable speed motor, which collects the transfer film support . This speed control is located in front of the fixture that supports the foil head, foil supply spool and take-up spool. Molding transfer system consisting of 4" rubber caterpillar type belts, and rubber wheels with ball bearing side wheel guides, and spring loaded top ball bearing wheel guides insure positive feed on the molding . The P.A.O. MACC. Multi-Head Foiling Machine will offer many years of accurate and superior quality, hot transfer foiling of any kind of profiles.

MAIN GENERAL DETAILS :

- ALL MACHINES ARE WITH INVERTER AND PLC SIEMENS FOR WORKING SPEED REGULATION AND ELECTRICAL AND ELECTRONIC FUNCTIONS

- ALL FOILING HEADS START FROM THE STAND BY TO THE WORKING POSITIONS AUTOMATICALLY , WITHOUT MANUAL OPERATION.

- PVC REWIND MOTOR - ELECTRONIC SELF-ADJUSTED - FOIL MECHANICAL SPRINGING COMPENSATOR DEVICE -

- FOIL MICROMETRIC ADJUSTMENT EVEN DURING PRODUCTION

- INDEPENDENT SIDE GUIDES WITH VERNIER SCALE FOR A PERFECT PROFILES ALIGNMENT

- SPRINGING INDEPENDENT UPPER PULLEYS WITH 4 DIFFERENT POSITIONS

- ALL MACHINES ARE DISPOSED WITH ELECTRICAL AUTOMATIC LINE FOR PRE-HEATERS (OPT)

- EASY SET-UP BY CONSOLES IN FRONT AND BACK SIDE OF EACH HEAD

- PLC DIAGNOSTIC SOFTWARE

|

MACHINE MODEL |

LENGTH mm. |

WIDTH mm. |

HEIGHT mm. |

WEIGHT Kg. |

HEADS NUMBER n. |

Installed power Kw.** |

Compressed air pressure Nl/min-SCFM /MAX |

Conveyor motor power /Inverter Kw. |

|

DC/1 |

1.400 |

1.400 |

2.100 |

800 |

1 |

7,0** |

30 - 1,07 |

0,75 |

|

DC/2 |

2.600 |

1.600 |

2.100 |

1.250 |

2 |

9,0** |

40 - 1,41 |

0,75 |

|

DC/3 |

3.800 |

1.600 |

2.100 |

1.700 |

3 |

15,0** |

70 - 2,47 |

1,1 |

|

DC/4 |

4.600 |

1.600 |

2.100 |

2.300 |

4 |

17,0** |

130 - 3,53 |

1,1 |

|

DC/5 |

5.100 |

1.600 |

2.100 |

2.800 |

5 |

19,0** |

160 - 5.65 |

2 |

|

DC/6 |

7.000 |

1.600 |

2.100 |

3.250 |

6 |

22,0** |

190 - 6,71 |

2 |

|

DC/7 |

7.800 |

1.600 |

2.100 |

3.650 |

7 |

28,0** |

220 - 7.77 |

2 |

|

DC/8 |

8.650 |

1.600 |

2.100 |

4.280 |

8 |

30,0** |

250 - 8,83 |

2 |

**With Included eventual pre-heaters > One for DC/1 - Dc/2 - No. Two for DC/3 -DC/4 - DC/5 - DC/6 - No. Three for DC/7 - DC/8

|

FOR ALL MODELS | |||||

|

Working Speed Mt/min. |

Working Level mm. |

Stamping Wheel Diameter mm. |

Stamping Wheels Size Max. mm. |

Stamping Shaft Diameter mm. |

Stamping Wheel Temperature °C |

|

3/28 or 7/40 |

870 |

200 |

80* |

25 |

SILICONE RUBBER MAX.240°C EMBOSSING STEEL WH. 350°C |

|

|

|

DIFFERENT SIZE AVAILABLE |

DIFFERENT SIZE AVAILABLE |

DIFFERENT SIZE AVAILABLE |

|

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2004 - paomacc -

info@paomacc.net