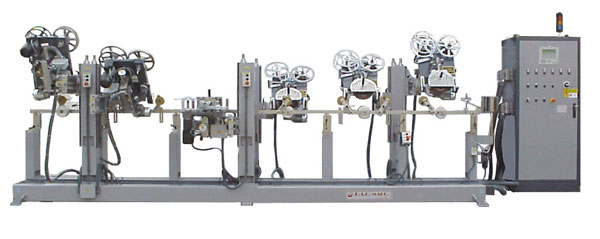

AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

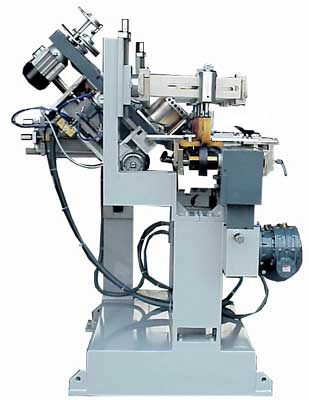

AUTOMATIC HOT STAMPING FOIL MACHINES FOR ANY PLASTIC MATERIALS

WORKING IN EXTRUSION LINE OR/AND INDEPENDENTLY, OUT-SIDE OF LINE

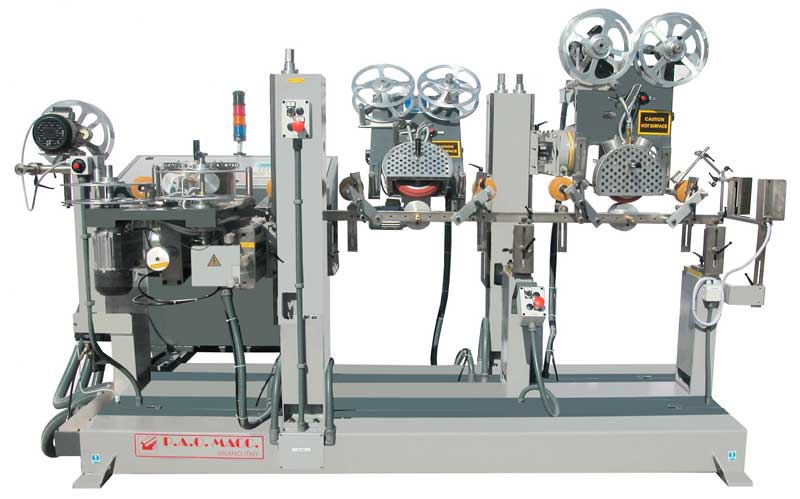

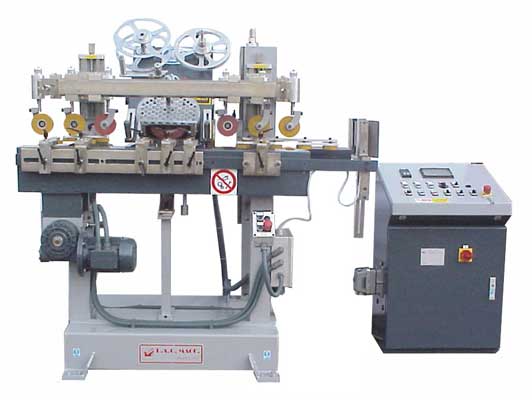

Intricate profiles, flat and/or shaping or compo surface, can be effectively foiled with the use of this machine.

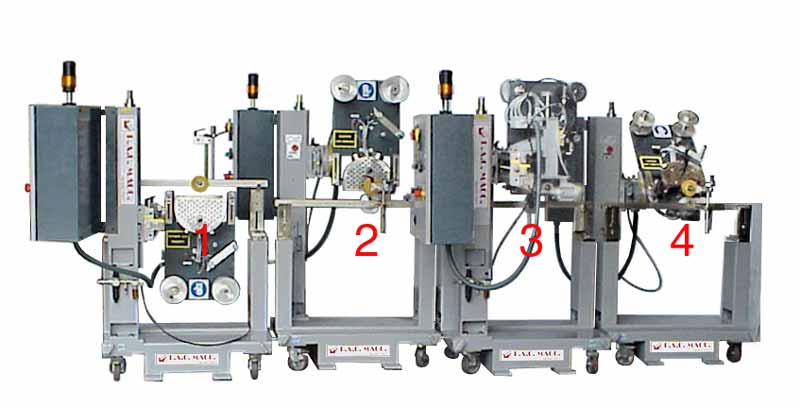

These machines can be configured to work in-line with an extrusion machine and/or independently. The in-line machine is constructed without any material feeding. The independent machine is built with drive rollers. A third version is a combination of line with assist material transport.

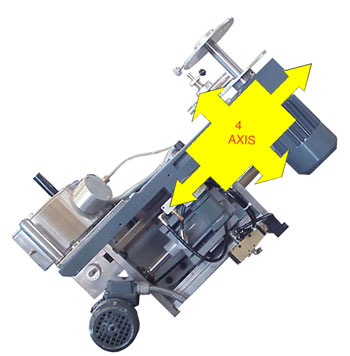

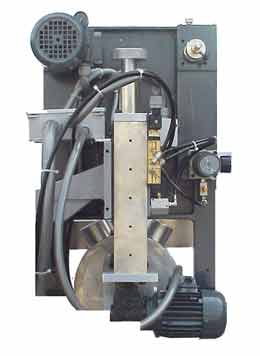

The DC/PVC Models are available with any number of heads, up to twelve (12), which are alternately placed, on either side of the machine, as specified. Each head is adjustable from -15° to 135°, by means of a veneer scale.

On the in line version of the machine each head is manually placed on the working profile by the operator, while on the independent machine the heads are completely automated and the activation of each head is controlled by a Siemens PLC.

Each standard foil head is heated with two 1000 watt special heaters surrounded by oven-like stainless steel housing. The surface temperature of the wheels is monitored by a special probe, with out any thermo-regulator > the thermo-regulation is electronically made by the PLC: the result of this control is perfect (These heaters are exceptionally efficient). As the foil is transferred, a take-up spool is electronically controlled through a variable electronic speed motor, which collects the transfer film support. This speed control is located in front of the fixture that supports the foil head and is easily controlled by the operator. The P.A.O. MACC. Multi-Head Foiling Machine will offer many years of accurate and superior quality, hot transfer foiling of any kind of plastic profiles.

OPTIONAL : -Embossing Heads with metal wheels.

-Special wide foil heads and transport feed for profiles up to a maximum width of 260 mm.

-Any others transport feed rollers for male and special profiles are available.

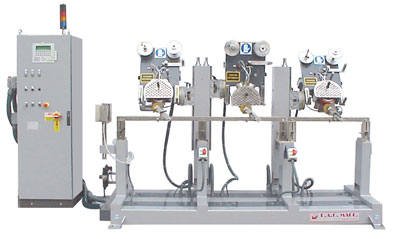

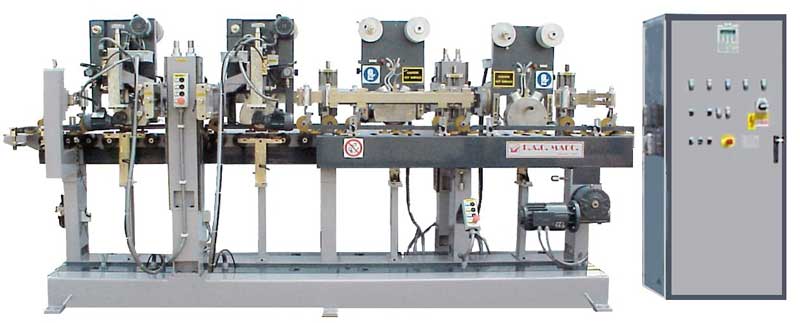

EXAMPLES : IN LINE MACHINES - WITHOUT ANY TRANSPORT DEVICE -

![]()

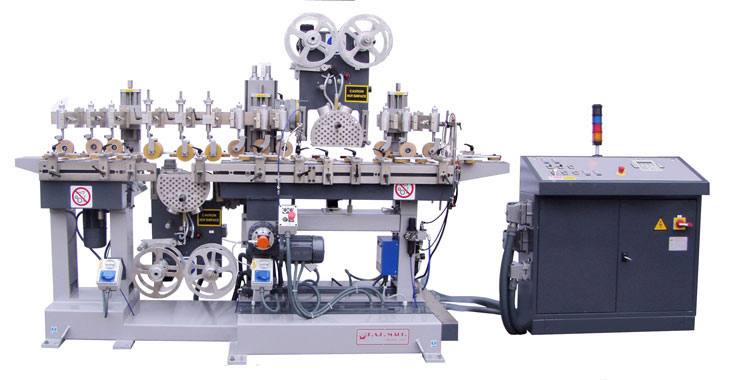

EXAMPLE OF INDEPENDENT AND/OR IN MACHINE - WITH ITS OWN TRANSPORT DEVICE -

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2004 - paomacc -

info@paomacc.net