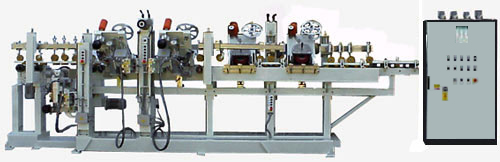

AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

THIS MACHINE APPLY HOT TRANSFER FOIL ( INK TYPE) ON ANY ALUMINIUM PROFILES

FOR EXTERNAL/INTERNAL APPLICATION

The machine consists of a solid structure of steel tubes and plates, welded together to provide maximum strength and stability. The machine is with a rubber drive rollers conveyor . They are connected together by a chain operated by two motors governed trough two inverters , so that any speed appropriate to the type of process can be selected: the working speed can be adjusted from 8 to 40 MT/minute.

The sliding columns are located laterally of the conveyor unit, together with the operator heads; the heads can be adjusted with just one handle to set-up the vertical and horizontal carriages as well as the joints.

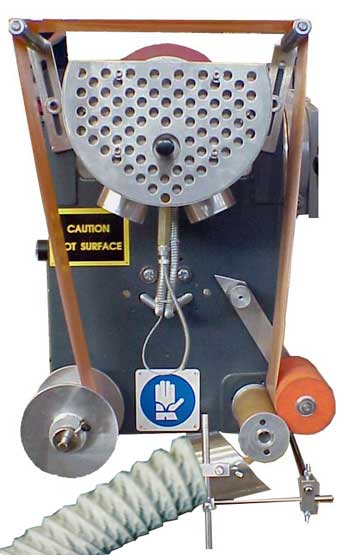

The heads are heated by two semicircular resistance of 2000 watts each ( 4000 watt each head) located in appropriate protective shrouds. Each heads can support rubber silicone wheels with height from 10 to 160 mm. ( Dia. 200 mm, ).

The surface temperature of the wheels is monitored by a special probe, with out any thermo-regulator > the thermo-regulation is electronically made by the PLC: the result of this control is perfect (These heaters are exceptionally efficient)

The silicone wheel is driven in rotation by the movement of the profiles and it only acquires its own motion in the non-operating position after a pneumatic clutch has been triggered.

The aluminum profiles must be pre-painted and heated before the foil processing. After the application no any protections is required.

The system for recovering the plastic OR PAPER film is driven by an electronic motor that can be easily regulated linearly, in relation to the power required; a rubber springing wheel stopped the paper. When the machine start to work the paper is take off by an aspirator tubes system located near the rewind motor.

All the heads start in operation automatically by A PLC SIEMENS.

All electrical and electronic controls are on a single control panel (except for the emergency push-buttons and those for setting the machine up: these are on the manual push-button console located around the body machine.

Technical Features:

LENGTH : 6.000 mm.

WIDTH : 1.600 mm.

HEIGHT : 2.000 mm.

WEIGHT: 2.800 KG.

Number of the foiling heads : No. 5

Installed power KW 28 :

Compressed air pressure 6 Bar (90 PSI)

Air requirements Max. 160nl/min - SCFM 5.65

Working speed 4-20 mt/minute

Conveyor motors power 1st. kW. 1.5 - 2nd. kW 0,75

Working Level 1.225 mm.

Stamping Wheel Dia 200 mm.

Stamping shaft Dia 25 mm.

FOILING HEADS DETAILS

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2004 - paomacc -

info@paomacc.net